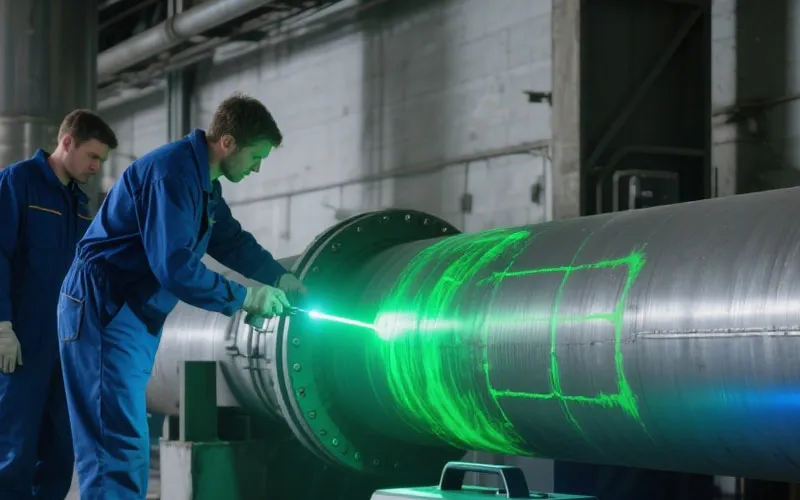

High precision flaw detection with advanced immersion technology

NCS Immersion Ultrasonic Testing Equipment delivers high precision flaw detection for metals, composites, and critical components. With advanced immersion technology, it ensures accurate results, fast scanning, and consistent reliability. Trusted by industries worldwide, NCS supports strict quality control, improved productivity, and superior ultrasonic inspection performance in demanding applications.

High precision flaw detection with advanced immersion technology

Consistent performance for metals, composites, and critical components

Trusted by aerospace, automotive, and energy industries

Immersion Ultrasonic Testing Equipment is widely applied for precise flaw detection, thickness measurement, and material evaluation in critical industries. In aerospace and aviation, it ensures aircraft component safety. In energy and power generation, it detects defects in turbines and pressure vessels. Automotive and machinery sectors use it for quality control of precision parts, while metallurgy and manufacturing apply it to inspect steel, aluminum, and titanium. Research institutions also rely on immersion UT for material analysis and R&D.

Expert Support, Customized Solutions, Go above and beyond: Welcome to NCS's World of Non-Destructive Testing.

NO.13, GAOLIANGQIAOXIE STREET, HAIDIAN DISTRICT, BEIJING, CHINA

Focusing on Pipeline Quality Inspection – NSC Will be Showcasing Its Products at The 2026 German Pipeline Exhibition

NCS Ultrasonic Testing System Sets Sail for Overseas Expansion

NSC Presents Automated Non-Destructive Testing Equipment At International Exhibitions