High-Speed, High-Resolution Flaw Detection for Conductive Materials

NCS Eddy Current Testing Equipment provides fast, accurate, and non-destructive inspection for metals, tubes, and critical components. With advanced sensors and high-resolution detection, it ensures reliable flaw identification, improved quality control, and increased productivity. Industries worldwide trust NCS for efficient, precise, and durable eddy current testing solutions.

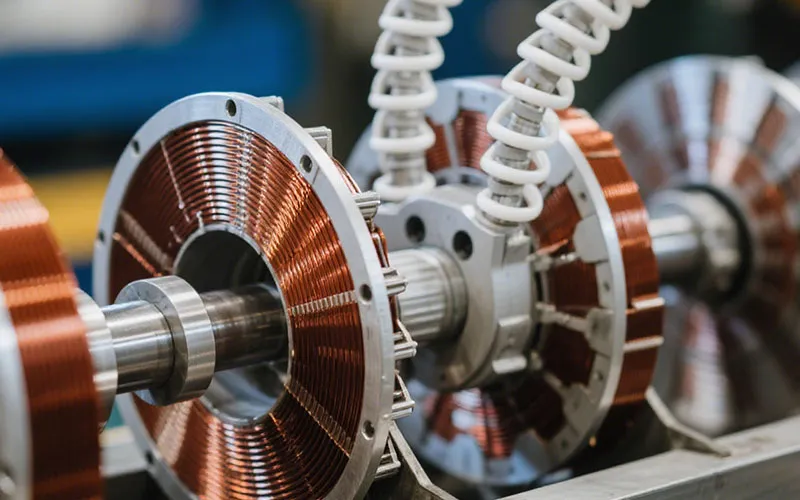

NCS Rotary ECT Equipment provides advanced surface and near-surface flaw detection for steel, aluminum, copper, titanium, and other metals. Trusted by industries including metallurgy, aerospace, nuclear, and power generation, it ensures material integrity, process safety, and reliable non-destructive testing performance for critical manufacturing applications worldwide.

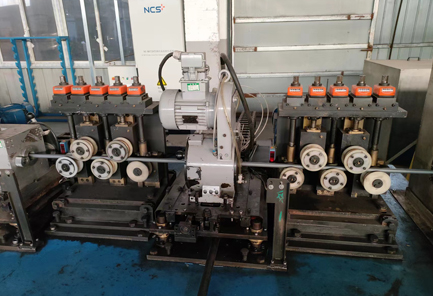

NCS Throughout ECT Equipment offers high-precision surface and near-surface flaw detection in steel, aluminum, copper, titanium, and other metals. Serving key sectors such as metallurgy, aerospace, power generation, aviation, and nuclear industries, it ensures reliable material evaluation, superior quality control, and enhanced safety in critical applications worldwide.

Penetrant Testing (PT) and Magnetic Particle Testing (MT) require extensive surface preparation, are messy with chemical use, and offer only surface-level detection. PT is ineffective on porous surfaces, while MT is limited to ferromagnetic materials. Both methods are slow, difficult to automate, and lack digital data records.

Eddy Current Testing (ECT) overcomes these by needing no contact or surface prep, providing immediate results, and detecting subsurface flaws. It is easily automated, delivers digital data for traceability, and is ideal for conductive materials.

Our eddy current technology excels in critical applications where precision and reliability are non-negotiable. It is indispensable for aerospace surface crack detection on aircraft skins and components. The eddy current testing equipment powers fast, in-service tube and heat exchanger inspection in power generation. The technology ensures integrity in automotive component testing (e.g., crankshafts, suspension parts). It is also vital for weld inspection and bolt hole examination across manufacturing and maintenance, providing unparalleled flaw detection in conductive materials.

Expert Support, Customized Solutions, Go above and beyond: Welcome to NCS's World of Non-Destructive Testing.

NO.13, GAOLIANGQIAOXIE STREET, HAIDIAN DISTRICT, BEIJING, CHINA

Focusing on Pipeline Quality Inspection – NSC Will be Showcasing Its Products at The 2026 German Pipeline Exhibition

NCS Ultrasonic Testing System Sets Sail for Overseas Expansion

NSC Presents Automated Non-Destructive Testing Equipment At International Exhibitions