NCS Magnetic Testing Equipment provides efficient and reliable non-destructive testing for ferromagnetic materials, welds, and components. With advanced magnetic particle inspection technology, it ensures accurate flaw detection, improved safety, and consistent performance. Industries worldwide trust NCS for durable, precise, and high-quality magnetic testing solutions that enhance quality control and productivity.

NCS MPI Testing Equipment for Plate and Strip utilizes the magnetic properties of ferromagnetic materials to evaluate microstructure, residual stress, and mechanical characteristics. This advanced technology enables quantitative nondestructive testing, accurate assessment of structural uniformity, and reliable performance, supporting quality assurance in demanding industrial applications worldwide.

NCS MPI Testing Equipment for Gear and Bearing applies advanced magnetic particle inspection technology to analyze the relationship between magnetic properties, microstructure, residual stress, and mechanical performance. It enables precise, quantitative nondestructive testing, ensuring accurate evaluation of stress, structure uniformity, and durability for critical industrial applications worldwide.

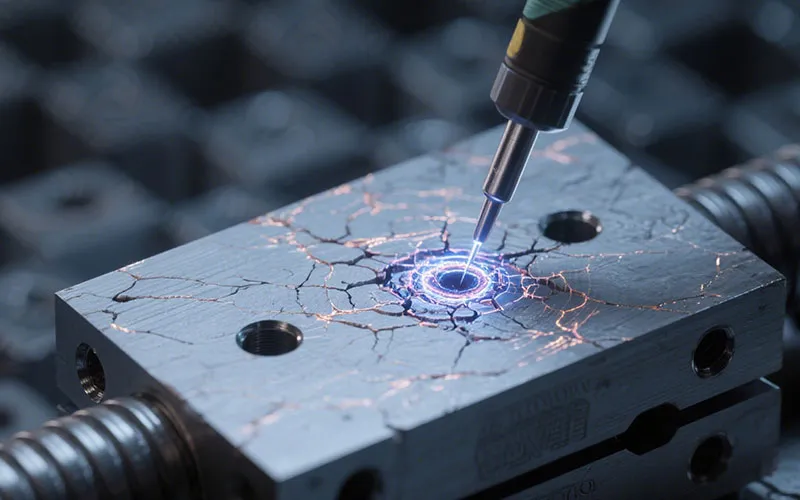

Magnetic Testing detects surface and near-surface flaws in ferromagnetic materials. The process first magnetizes the component. Where defects like cracks are present, the magnetic field is disrupted, causing flux leakage to escape from the surface. In Magnetic Particle Inspection (MPI), iron particles are applied and are attract to these leakage fields, forming a visible indication exactly outlining the flaw. This creates a direct, visual map of the defect, making results immediate and highly interpretable.

Magnetic Particle Inspection (MPI) remains an industrial workhorse due to its unmatched combination of reliability, cost-effectiveness, and simplicity. It provides immediate, visible results with exceptional sensitivity to surface-breaking flaws, requiring minimal training to interpret. Its portability allows for use in any environment, from workshops to remote field sites. Unlike more complex methods, MPI needs no elaborate setup, offering a robust, trusted solution for ensuring the structural integrity of critical ferromagnetic components.

Expert Support, Customized Solutions, Go above and beyond: Welcome to NCS's World of Non-Destructive Testing.

NO.13, GAOLIANGQIAOXIE STREET, HAIDIAN DISTRICT, BEIJING, CHINA

Focusing on Pipeline Quality Inspection – NSC Will be Showcasing Its Products at The 2026 German Pipeline Exhibition

NCS Ultrasonic Testing System Sets Sail for Overseas Expansion

NSC Presents Automated Non-Destructive Testing Equipment At International Exhibitions